Share To:

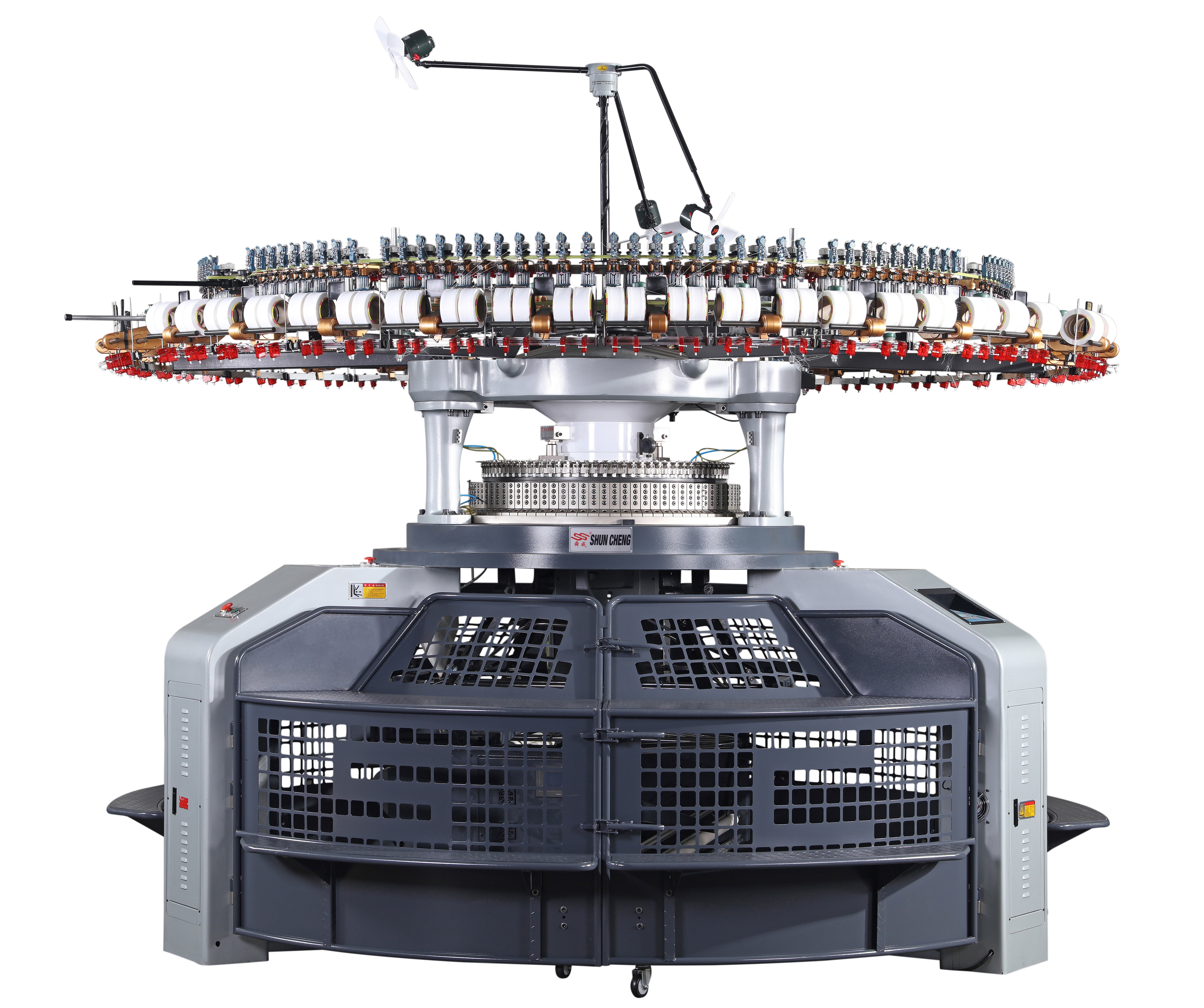

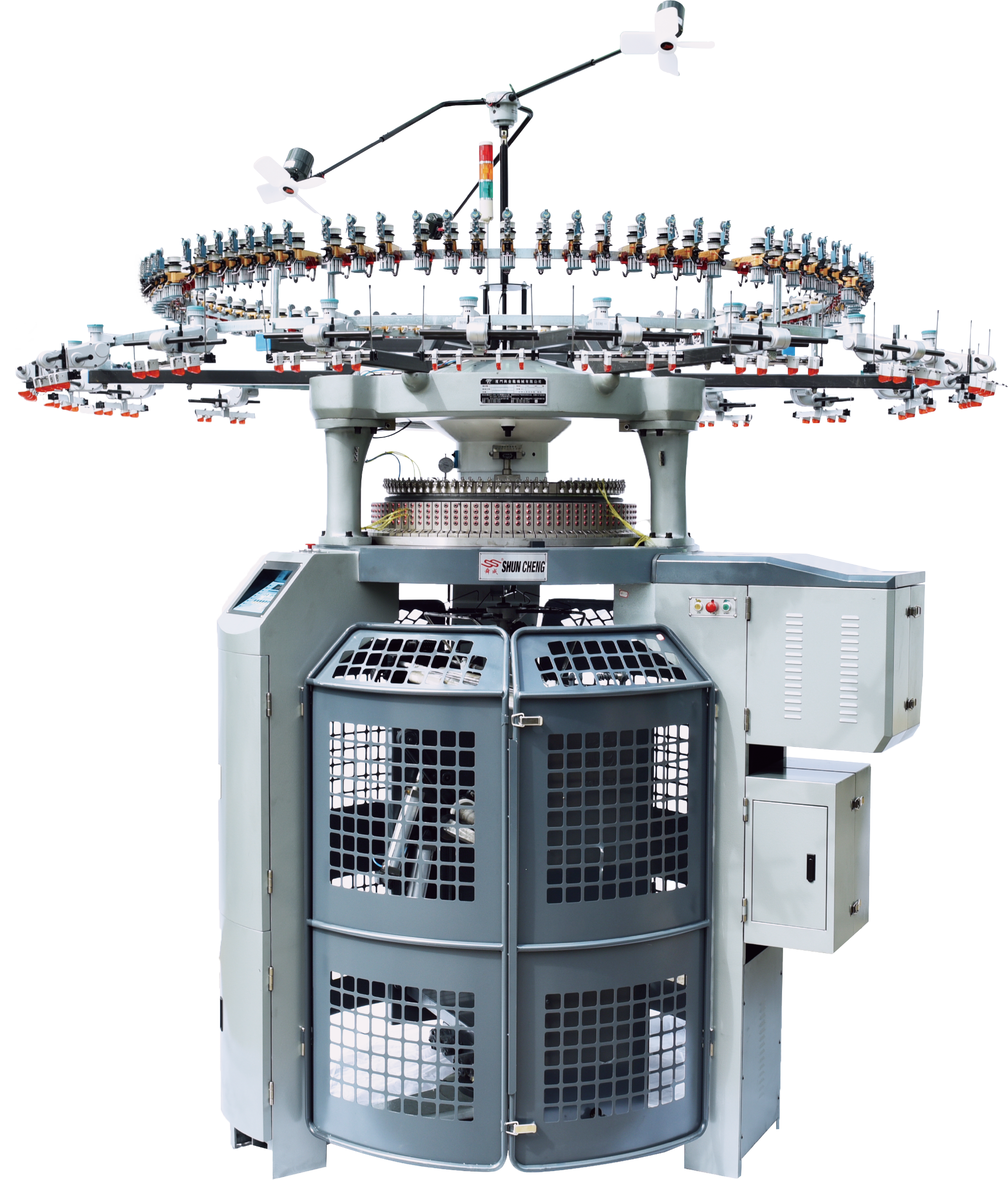

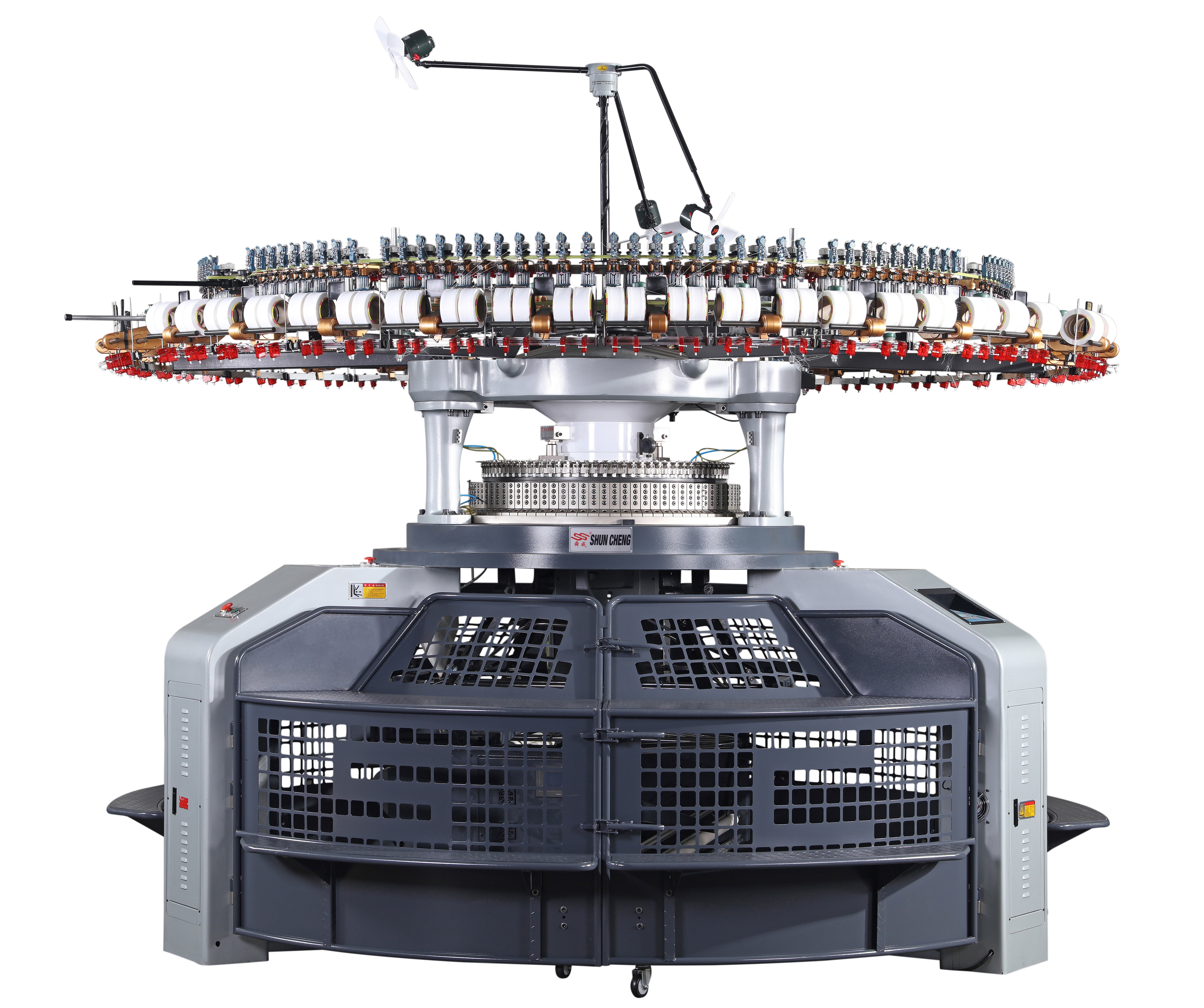

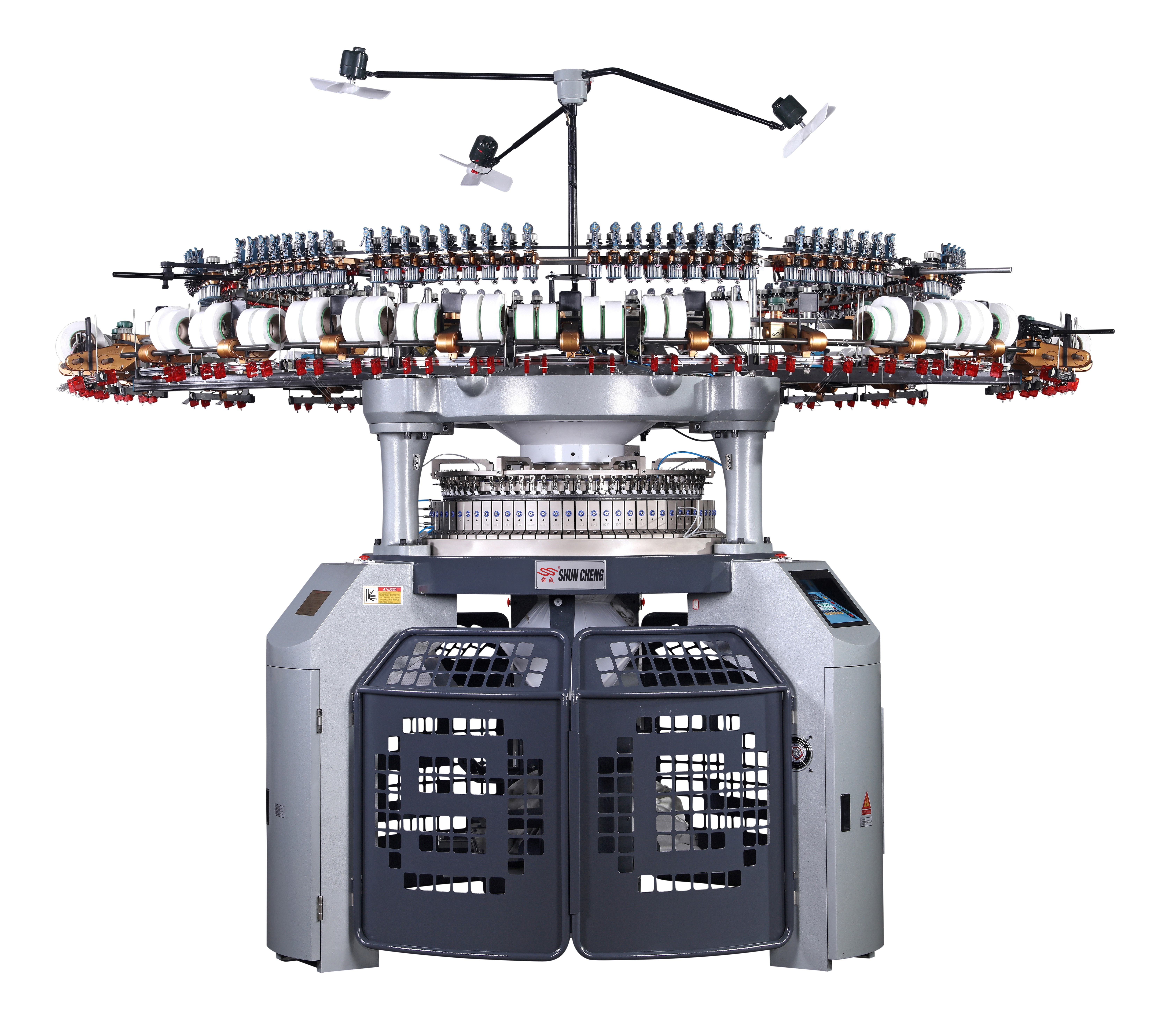

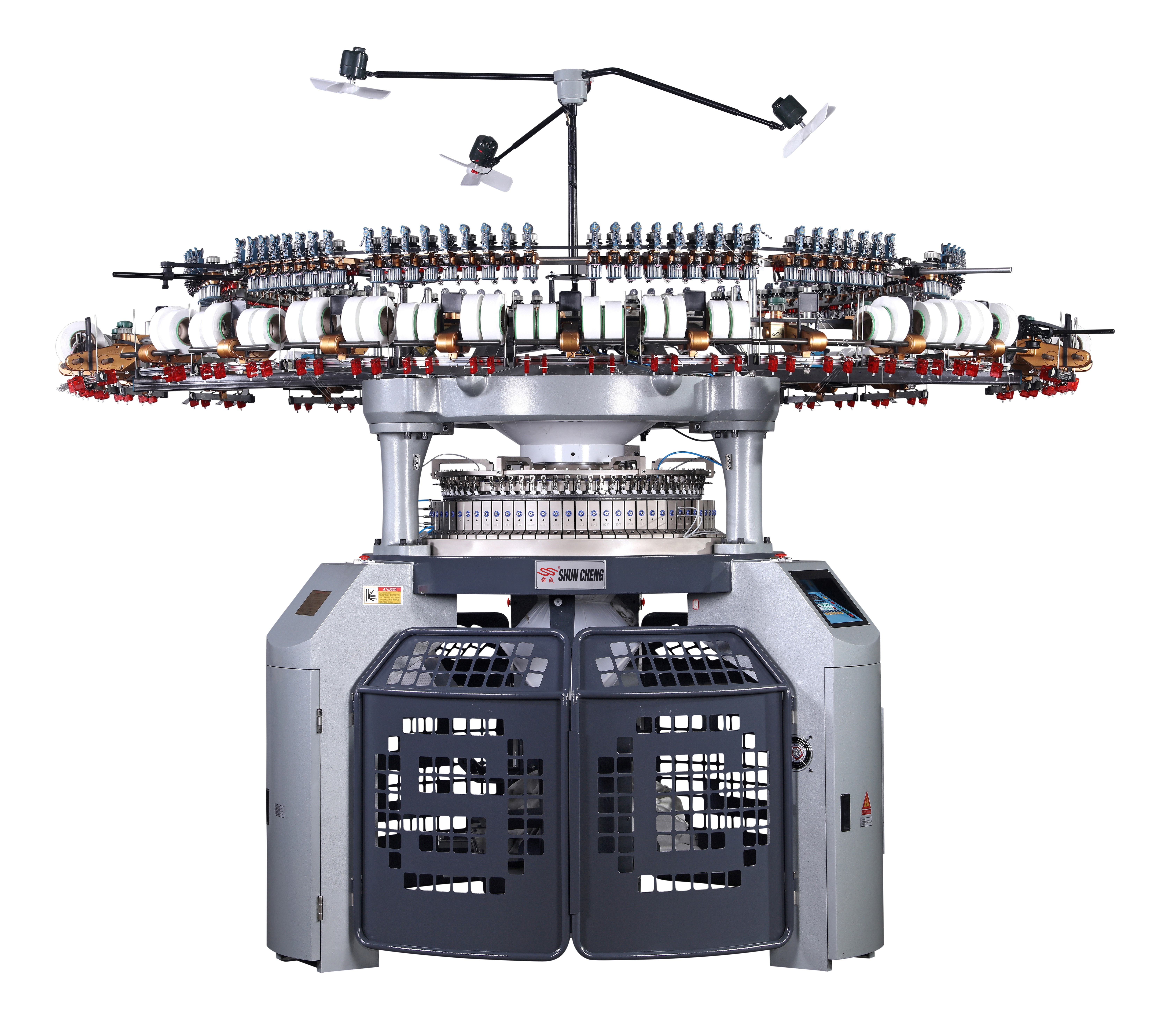

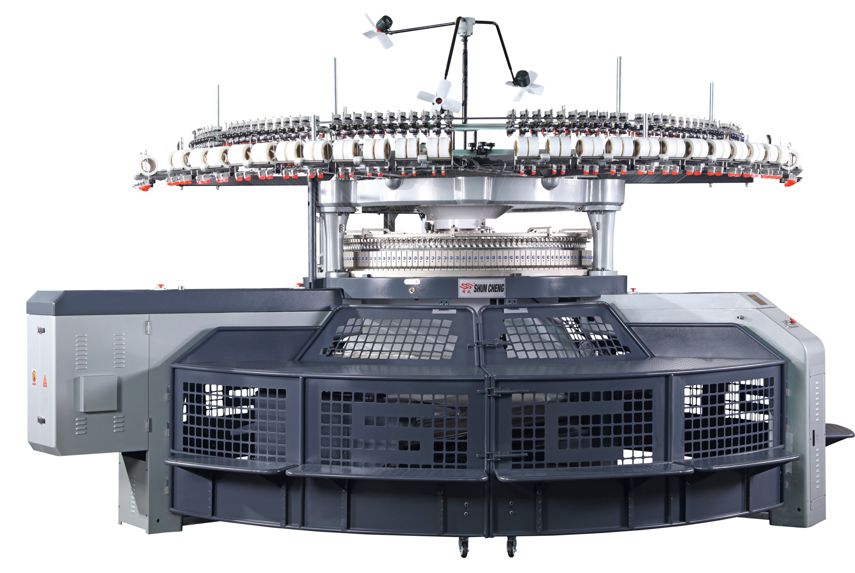

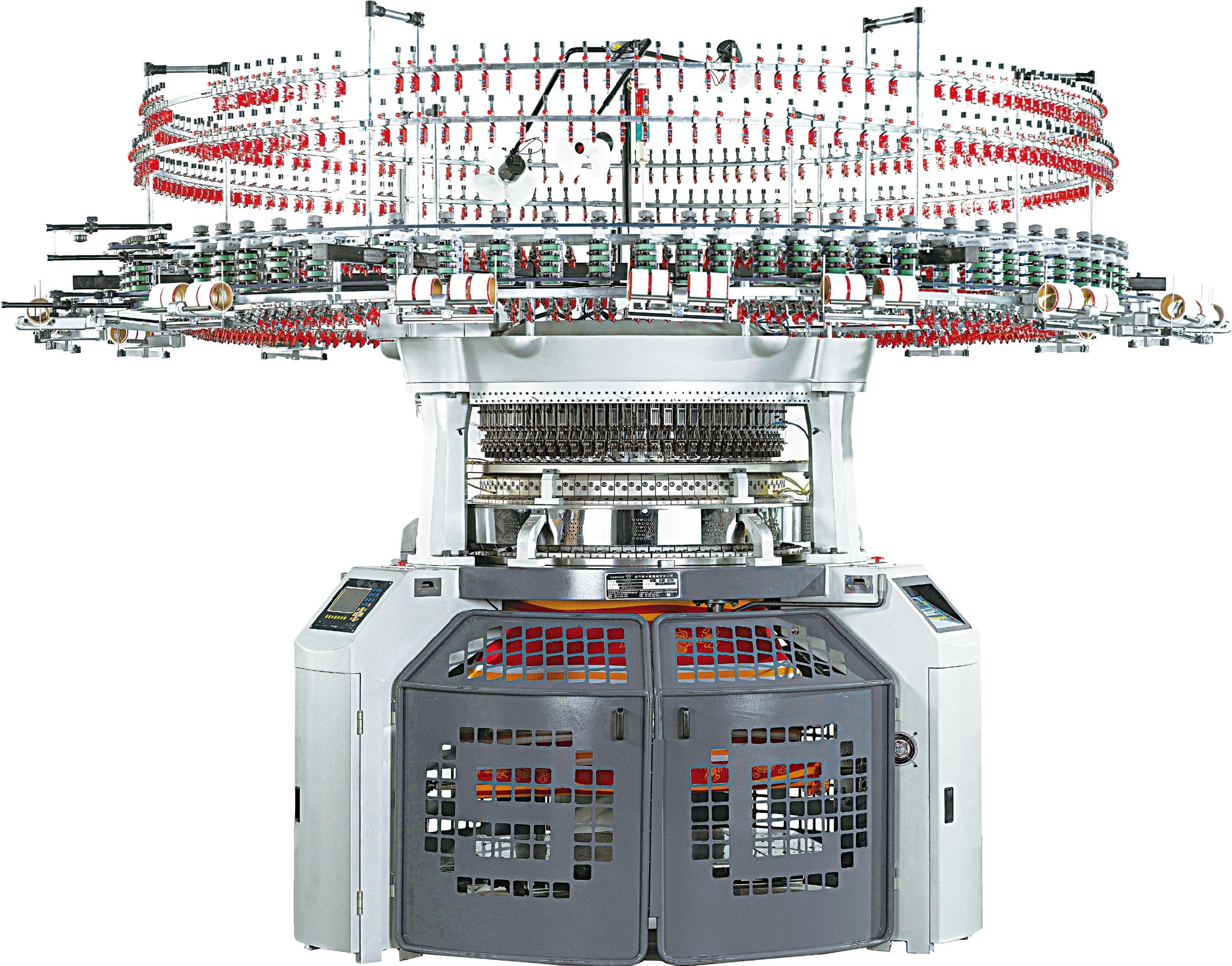

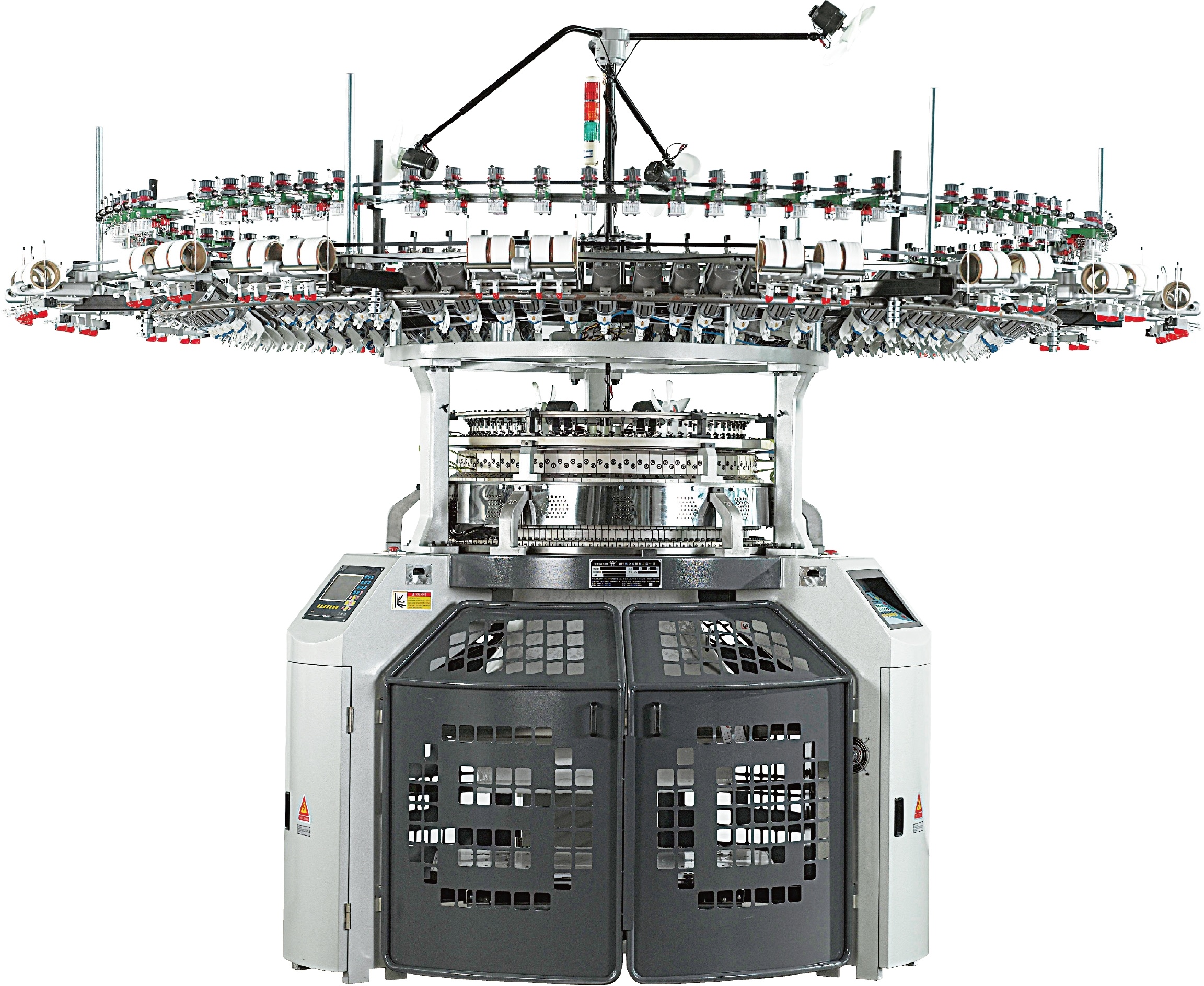

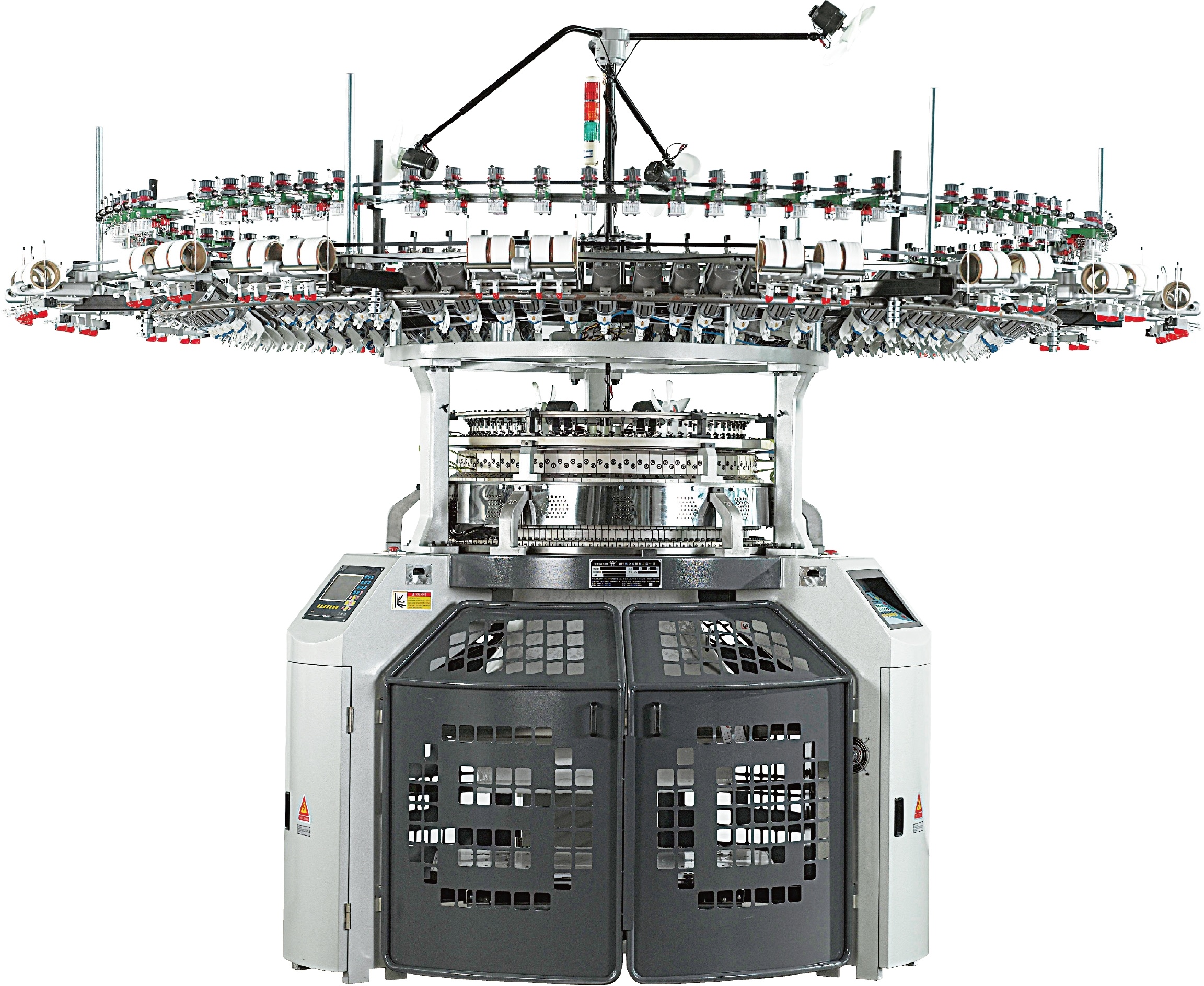

Single Jersey 4 Tracks Circular Knitting Machine

Model:

SC-BF

Diameter:

8”-60”

Gauge:

12G-44G

Feeder:

3F/inch-4F/inch

Classification:

Product Introduction

- Description

- Applied Fabric

- Features

- Specification

-

- Commodity name: Single Jersey 4 Tracks Circular Knitting Machine

- Model:: SC-BF

- Diameter:: 8”-60”

- Gauge:: 12G-44G

- Feeder:: 3F/inch-4F/inch

The machine is better in heat dissipation, ease of operation, low failure rate and is capable of knitting various fabrics. The machine adopts four tracks on cylinder which provide the machine more maneuverability, smaller distance, easier and precise adjustment. It can help to manufacture all kinds of single jersey fabrics. Applicable material: cotton, synthetic fiber, blending, silk and artificial wool etc.

SC-BF

Single Jersey 4 Tracks Circular Knitting Machine

technical data

model

diameter

gauge

feeders

SC-BF

8”-60”

12G-44G

3F/inch- 4F/inch

The machine is better in heat dissipation, ease of operation, low failure rate and is capable of knitting various fabrics.

The machine adopts four tracks on cylinder which provide the machine more maneuverability, smaller distance, easier and precise adjustment. It can help to manufacture all kinds of single jersey fabrics.

Applicable material: cotton, synthetic fiber, blending, silk and artificial wool etc.

One of the most significant benefits of the single jersey circular knitting machine is its high production speed. These machines are equipped with multiple feeders and can operate at continuous high speeds, enabling manufacturers to produce large quantities of fabric in a relatively short time. This efficiency helps meet the demands of fast-fashion and large-scale apparel production, reducing lead times and increasing overall throughput.

Another key advantage is the versatility of the single jersey circular knitting machine. It can process a wide range of yarn types, including cotton, polyester, spandex, wool, and blended fibers. This flexibility allows manufacturers to create fabrics with different properties—such as elasticity, moisture-wicking, breathability, or warmth—to meet diverse market needs. Additionally, by using various needle selections and cam settings, the machine can produce an array of knit structures, including plain knit, lacoste, piqué, and mesh designs.

-

2*1, 2*2 Rib with Lycra, Plain interlock fabrics, elastic health cloth, twill, air layer, interlayer pad, bubble cloth, double mesh, mercerized cotton and other color textures.

-

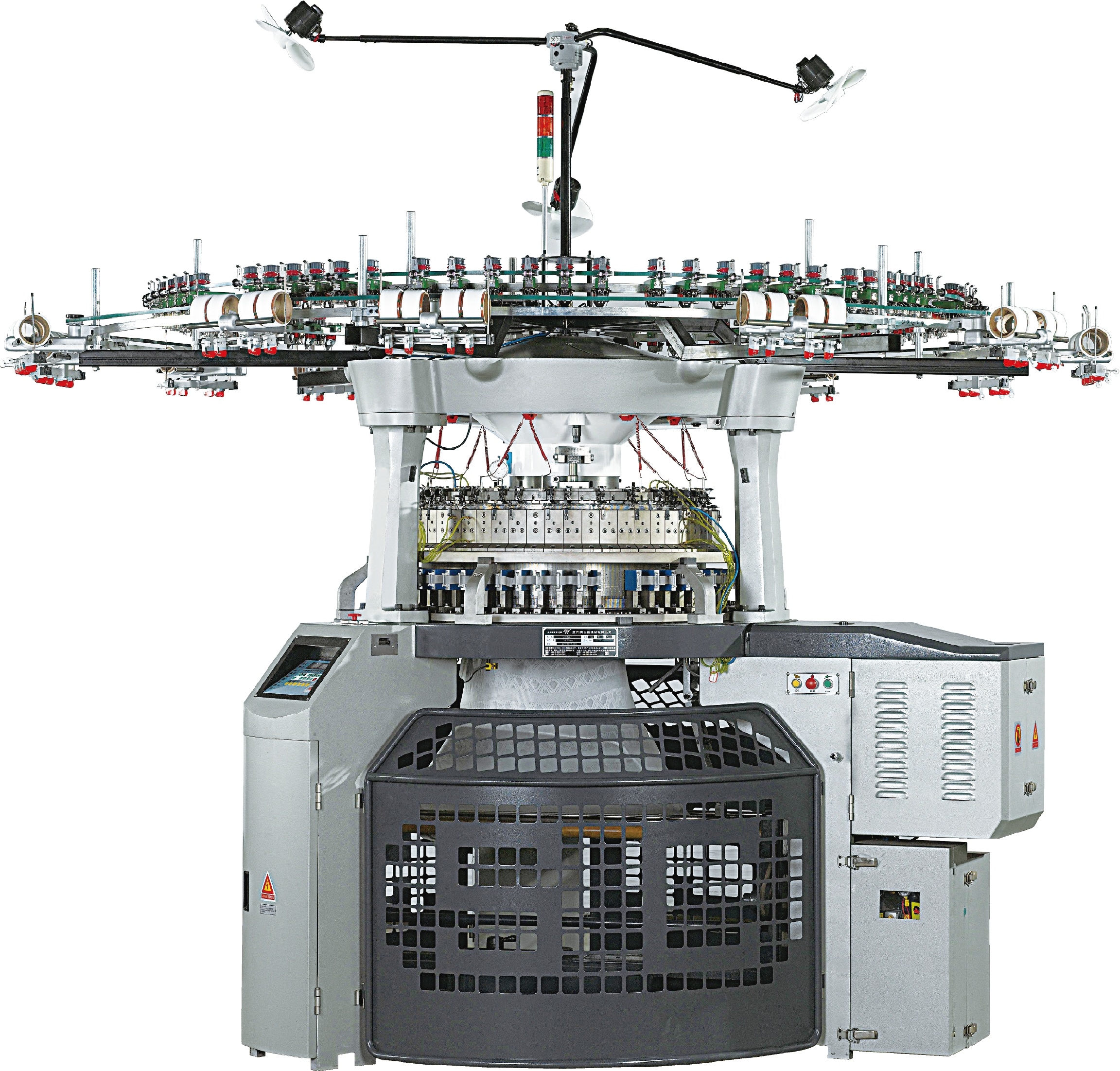

1, Run smoothly and stably equipped with oil bath wire racing bearing system.

2, Clear display and easily touch control panel, a benefit for machine operator.

3, Start torque and brake adjustable using Inverter A.C. motor controller.

4, 100% whole alloy steel main transmission shaft to provide dial & cylinder movement synchronized to eliminate any vibration.

5, Gauge change easily with special design for the dial arrangement

6, High quality of cylinder with additional inserted trick walls -

Diameter: 11'' ~44''

Gauge: 16G ~40G

Feeder: 22F~88F

Used for pure cotton, chemical fiber, mixed fiber, silk...

Key words:

Circular Knitting Machine

Double Jersey Knitting Machine

Price of circular knitting machine

Interlock Fabric

Rib Fabric

Double Jersey fabric

single jersey circular knitting machine

Previous:

Related Products

Single Jersey Knitting Machine

-

Single Jersey 4 Tracks Circular Knitting Machine

The machine is better in heat dissipation, ease of operation, low failure rate and is capable of knitting various fabrics. The machine adopts four tracks on cylinder which provide the machine more maneuverability, smaller distance, easier and precise adjustment. It can help to manufacture all kinds of single jersey fabrics. Applicable material: cotton, synthetic fiber, blending, silk and artificial wool etc.

-

Single Jersey 4 Tracks Open Width Knitting Machine

Single jersey open width circular knitting machine is the machine which is used to produce many kinds of single jersey fabrics. Four track cams structure and universal needles which make it lower cost. Gears adopt oil-soaking design, through special treatment to prolong the life of gears and lower noise and quick rotation. Adopt open width system, make fabrics no fold mark and make the totally usage of fabrics, no waste of fabrics to reduce the cost.

-

Single Jersey Three-thread Fleece Circular Knitting Machine

-

Single jersey Terry circular knitting machine

Ce single jersey circular knitting machine Is One of the Main Spots Products of XING-QUANLONG With the Best Quality,With Professional Production Facilities,Welcome to Call

-

Single Jersey 4 Tracks Open Width Knitting Machine(high gauge)

Single jersey open width circular knitting machine is the machine which is used to produce many kinds of single jersey fabrics. Four track cams structure and universal needles which make it lower cost. Gears adopt oil-soaking design, through special treatment to prolong the life of gears and lower noise and quick rotation. Adopt open width system, make fabrics no fold mark and make the totally usage of fabrics, no waste of fabrics to reduce the cost.

Double Jersey Knitting Machine

-

Double Jersey Open Width Circular Knitting Machine

-

High Frame Double Jersey Interlock/Rib Knitting Machine

-

Double Jersey Open Width Circular Knitting Machine (high gauge)

-

Double Jersey Interlock Circular Knitting Machine

-

Double Jersey Rib Circular Knitting Machine

-

60” Double Jersey Open Width Circular Knitting Machine

Jacquard knitting machine

-

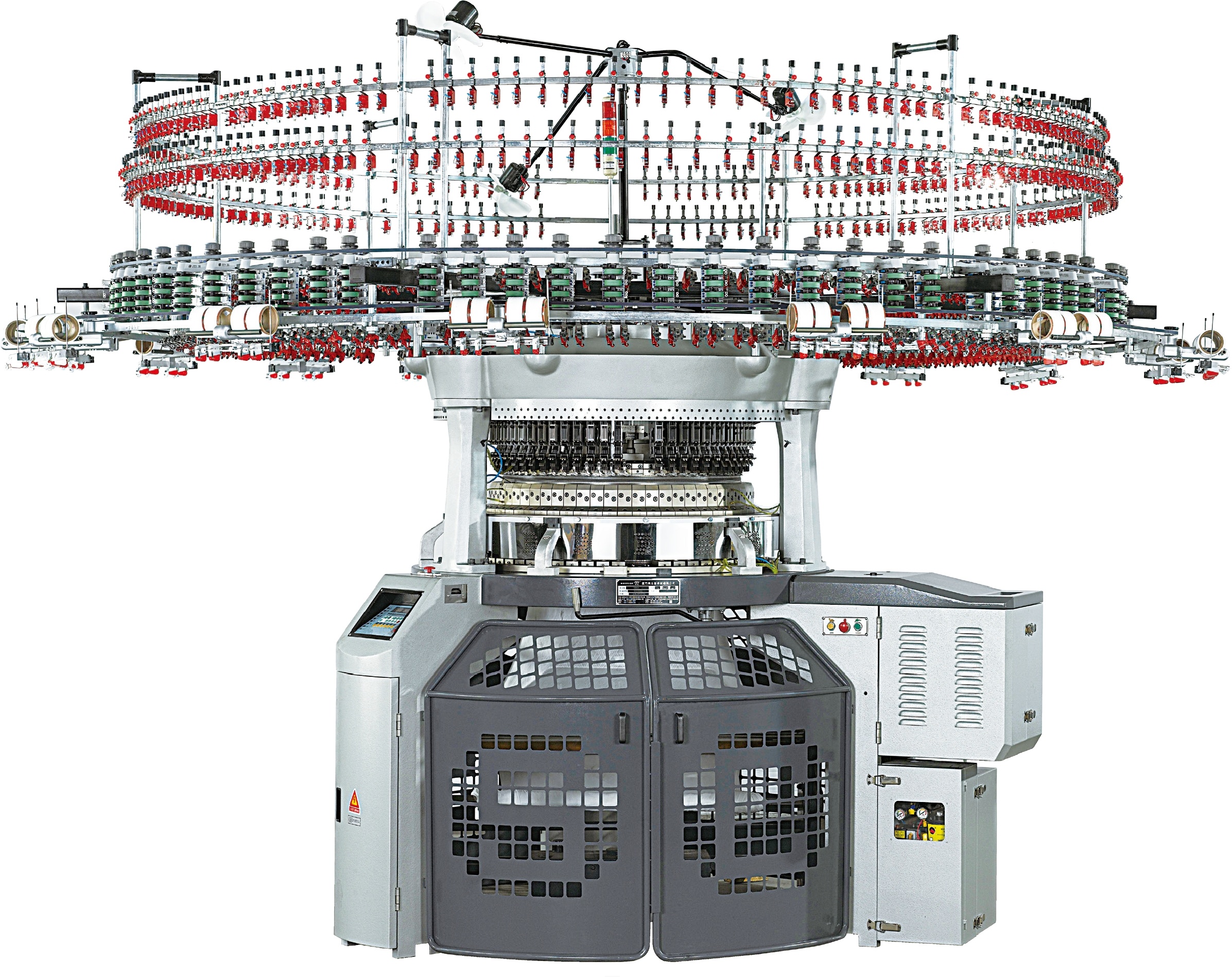

Double Jersey Computerized Jacquard Open Width Circular Knitting Machine

-

Double Jersey Computerized Jacquard Circular Knitting Machine

-

Double Transfer Rib Computerized Jacquard Knitting Machine

-

Double Jersey 4/6 Colors Full Computerized Auto Stripper Circular Knitting Machine

-

Single Jersey 4/6 Colors Full Computerized Auto Stripper Circular Knitting Machine

-

Single Jersey Computerized Jacquard Circular Knitting Machine

-

High Pile Computerized Jacquard Knitting machine

-

Single Jersey Computerized Mesh Jacquard Circular Knitting Machine

XING-QUANLONG: Your trusted jacquard circular knitting machine suppliers. We provide advanced, efficient textile solutions for global manufacturers. Partner with innovation

2.0 Intelligent Knitting Machine

Ask For A Quick Quote

We will contact you within 1 working day, please pay attention tothe email with the suffix "@xmgdab.com"