Share To:

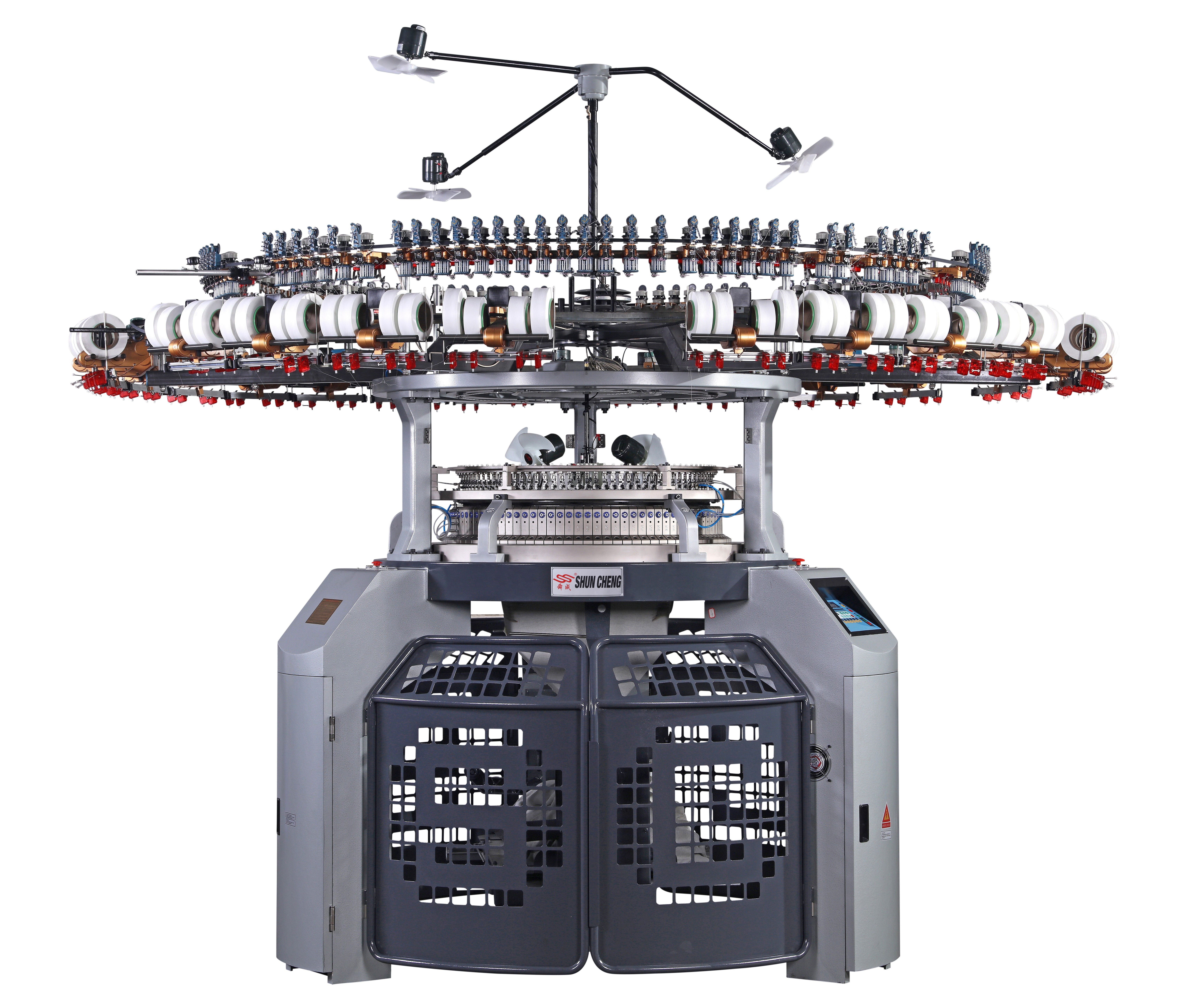

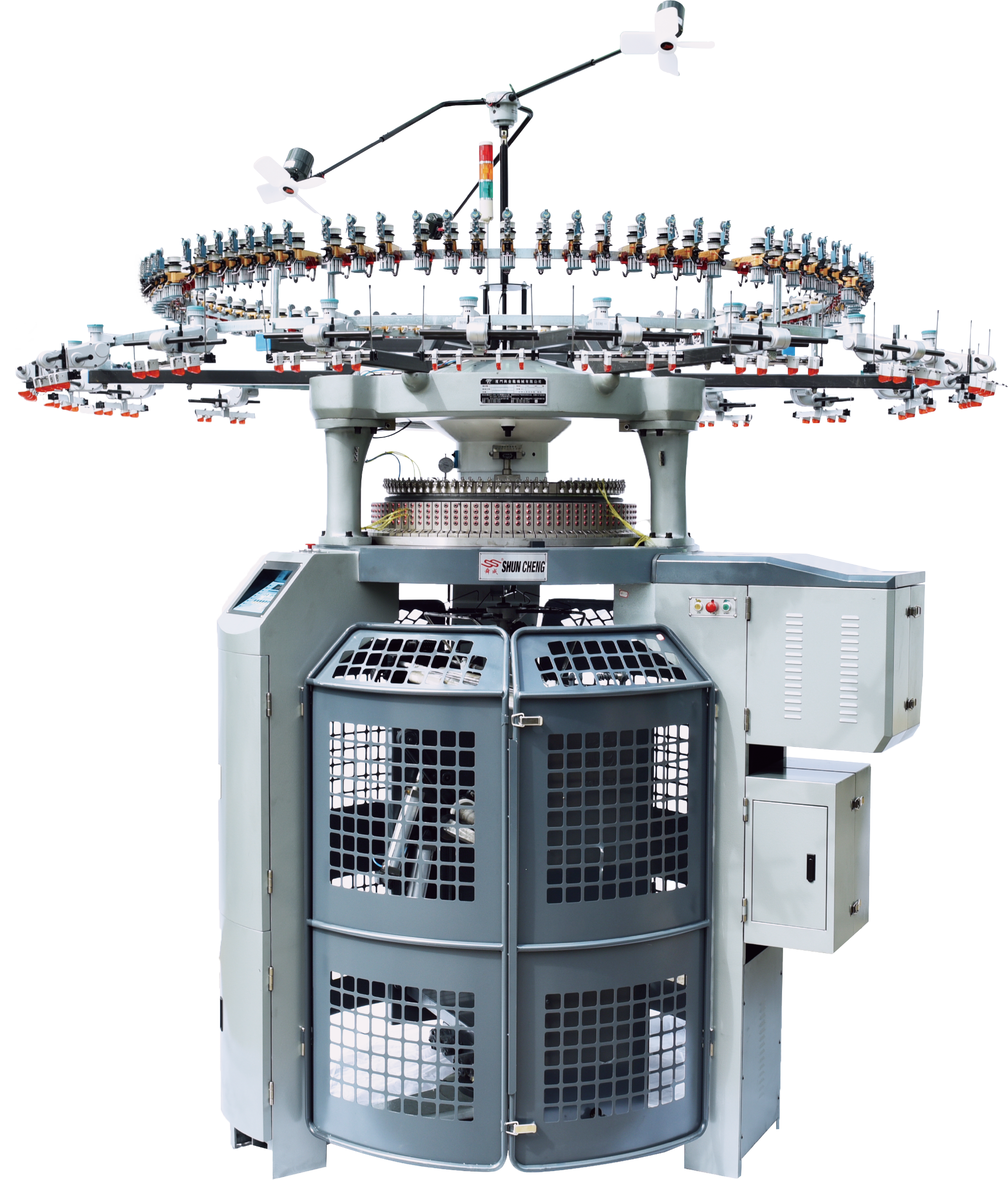

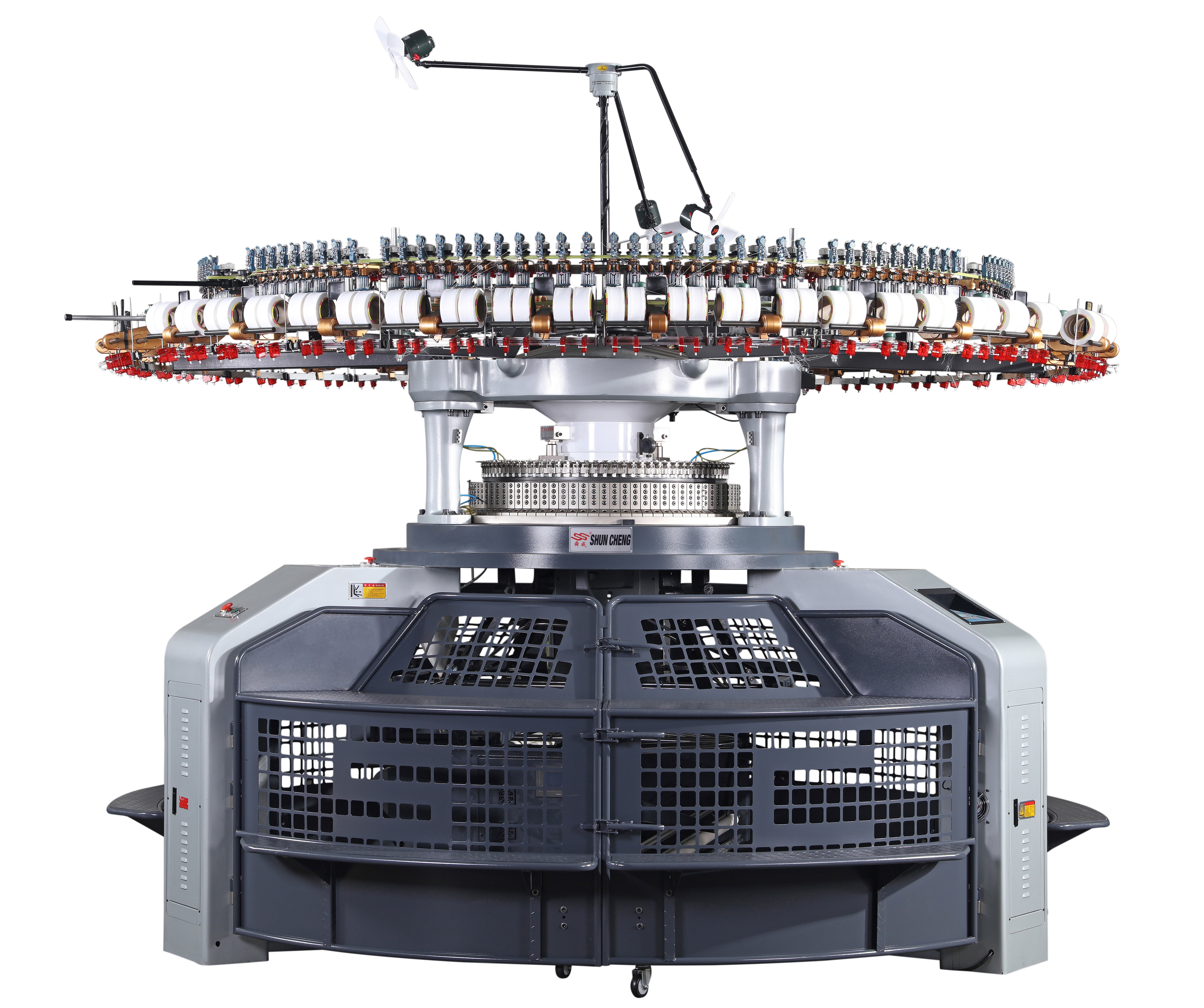

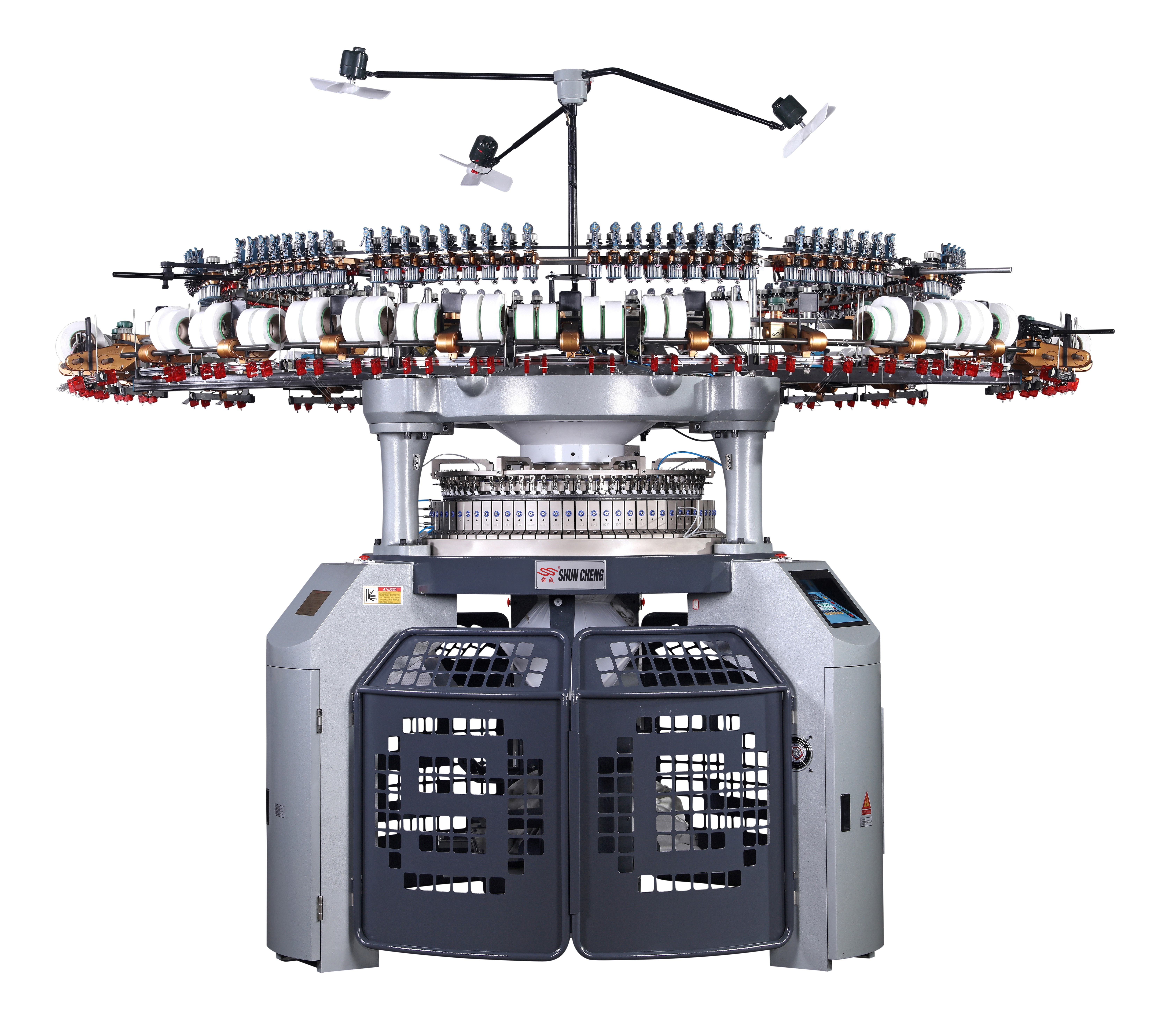

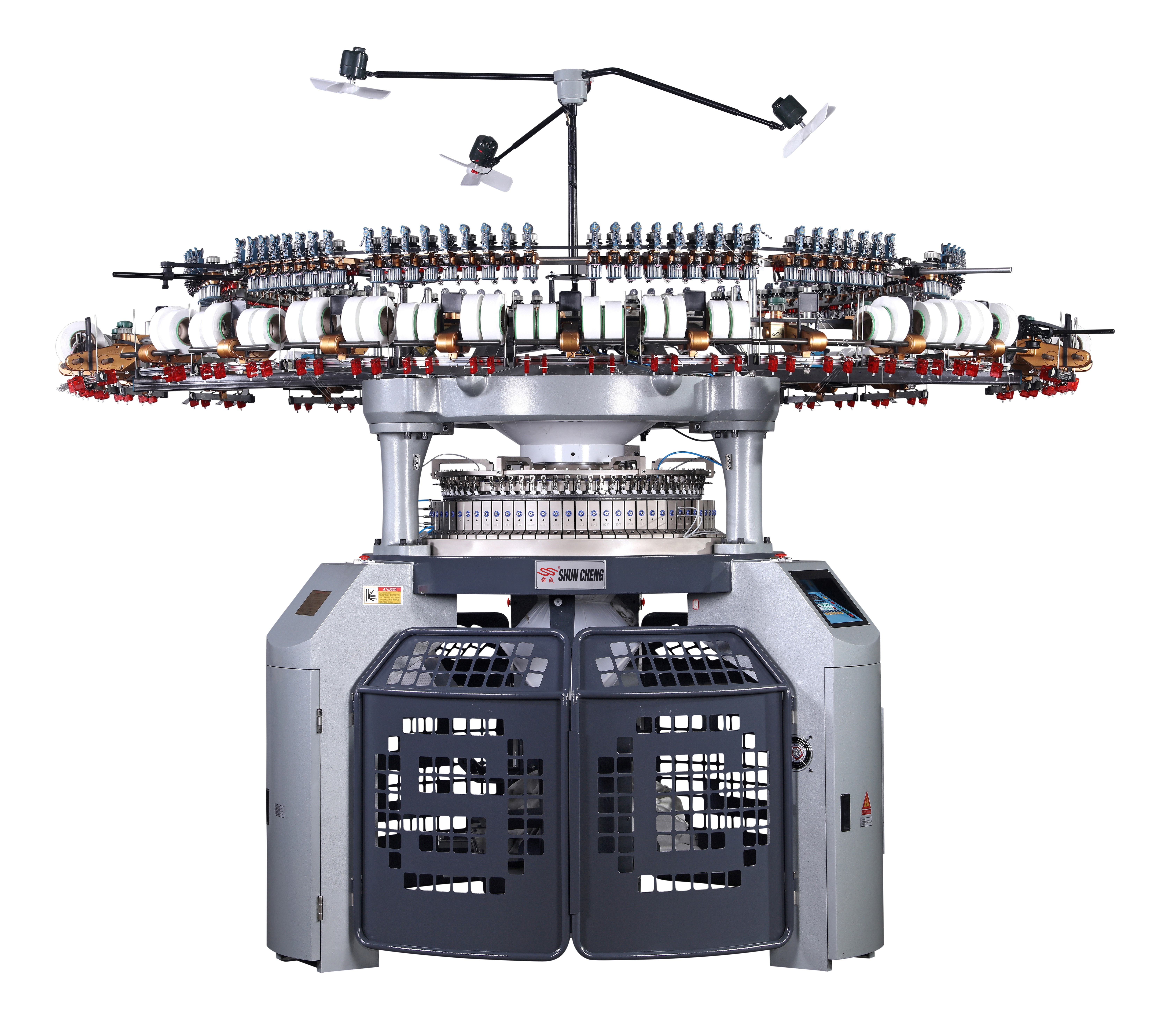

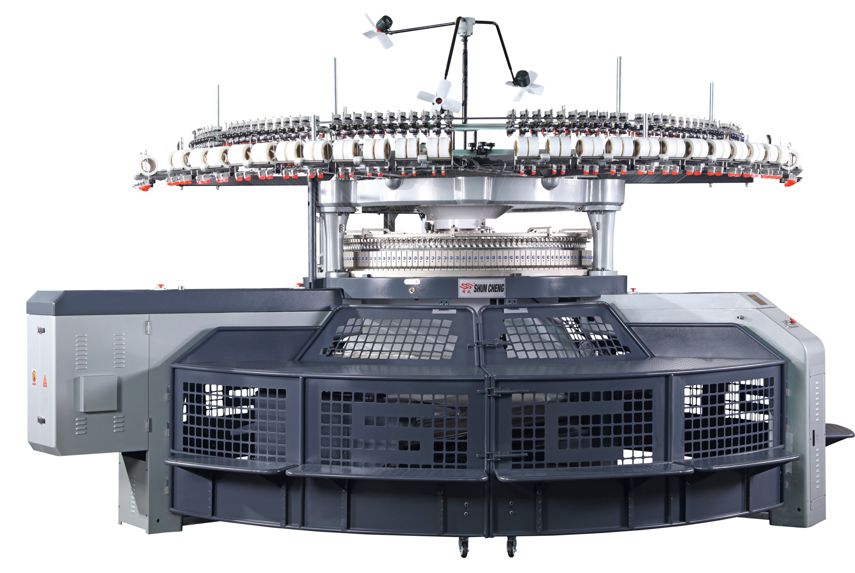

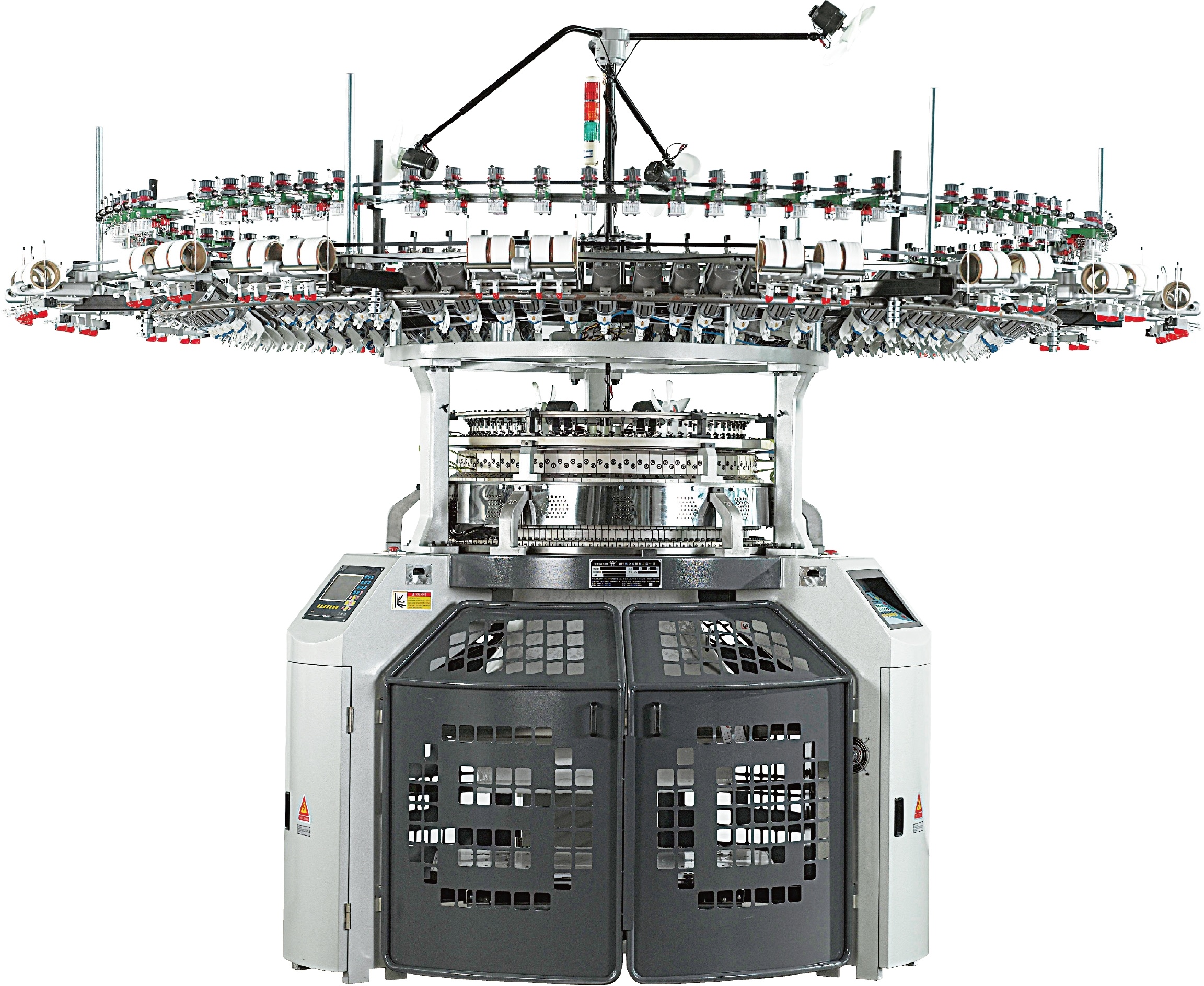

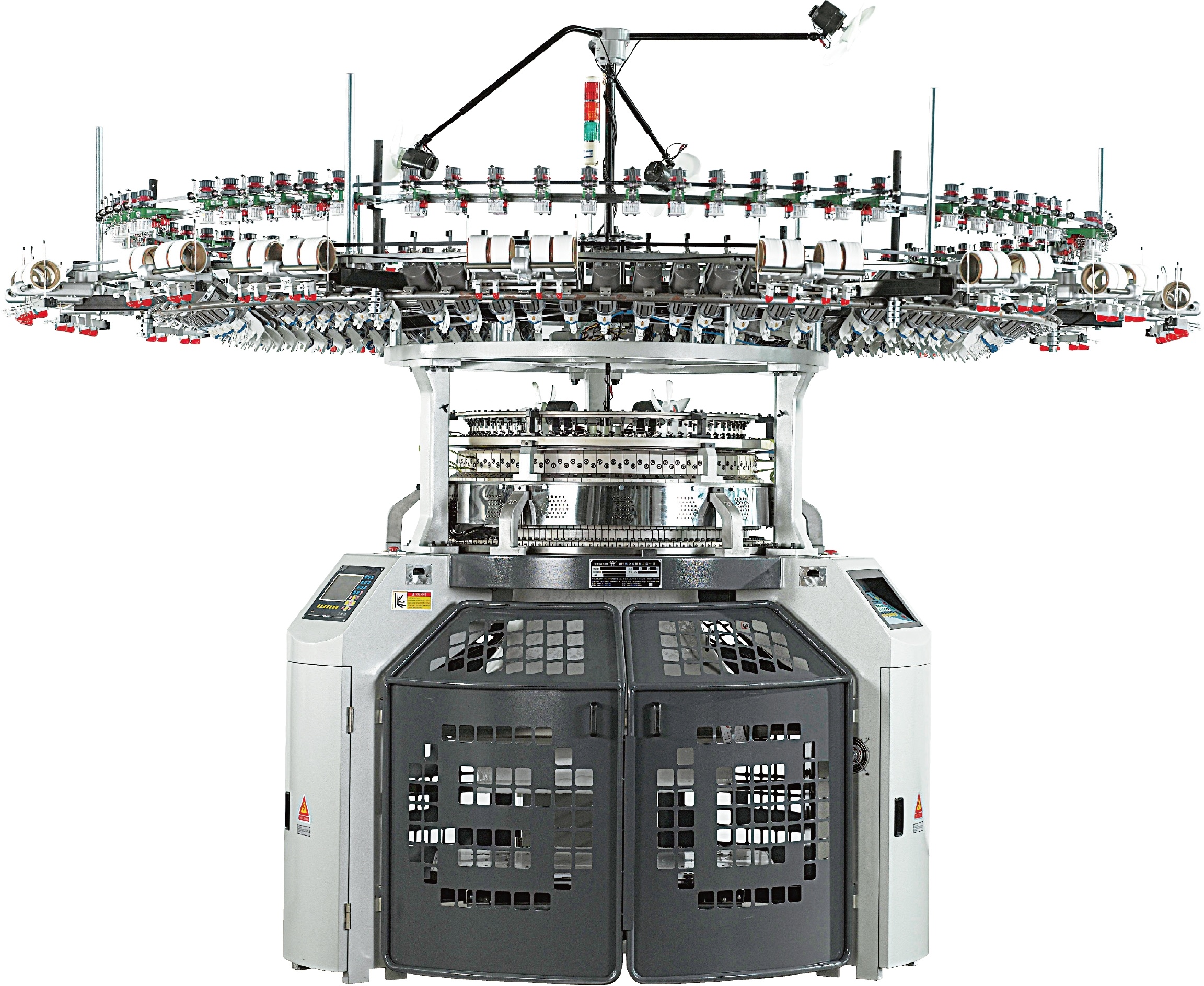

Single Jersey Computerized Jacquard Circular Knitting Machine

Model:

SC-SEJ

Diameter:

30’’- 38’’

Gauge:

16G- 36G

Feeder:

60-80F

Classification:

Product Introduction

- Description

- Applied Fabric

- Features

- Specification

-

- Commodity name: Single Jersey Computerized Jacquard Circular Knitting Machine

- Model:: SC-SEJ

- Diameter:: 30’’- 38’’

- Gauge:: 16G- 36G

- Feeder:: 60-80F

SC-SEJ

Single Jersey Computerized Jacquard Circular Knitting Machine

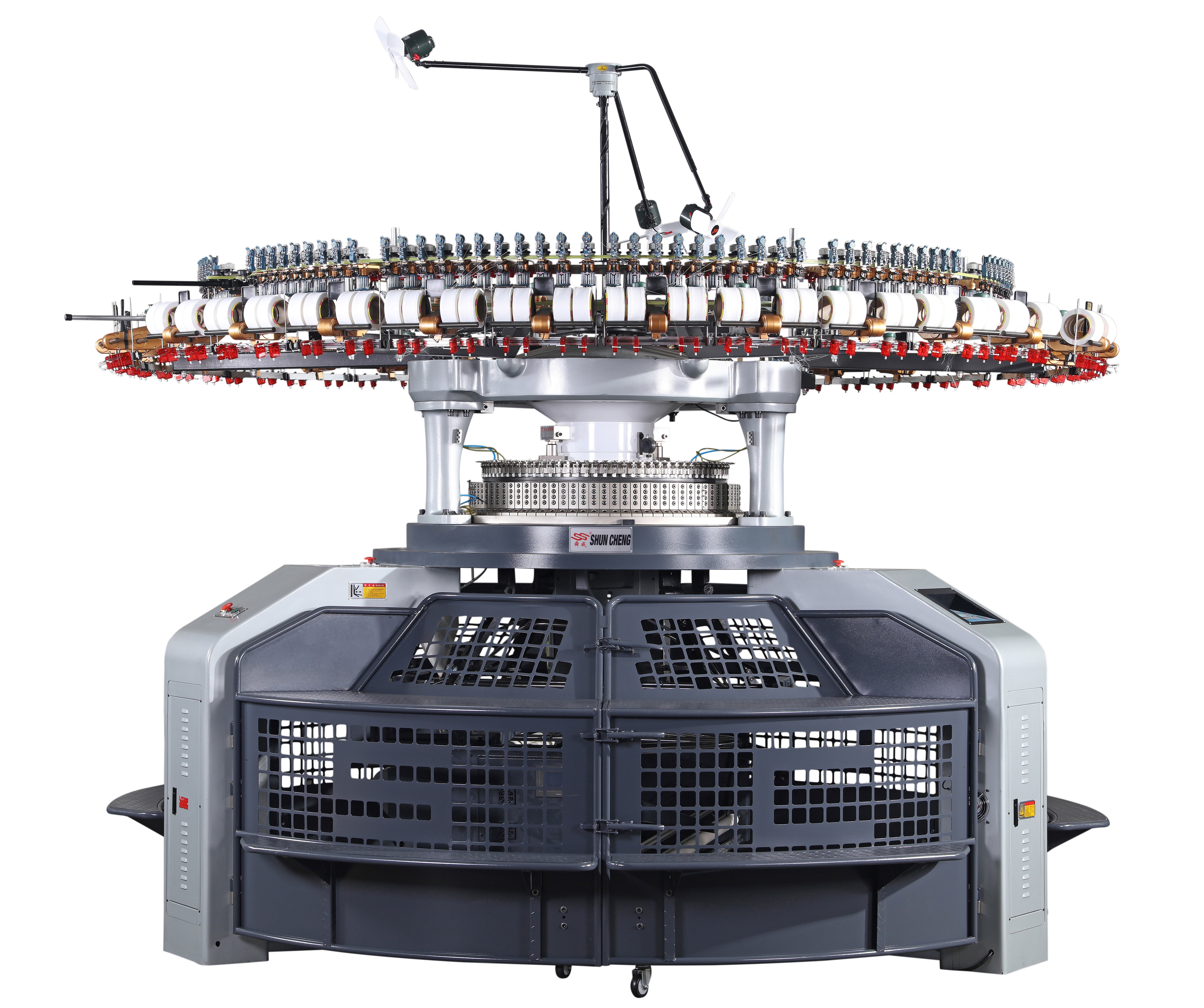

technical data

model

diameter

gauge

feeders

material

SC-SEJ

30”-38”

16G -36G

64F – 80F

Pure cotton、chemical fiber and mixed fiber

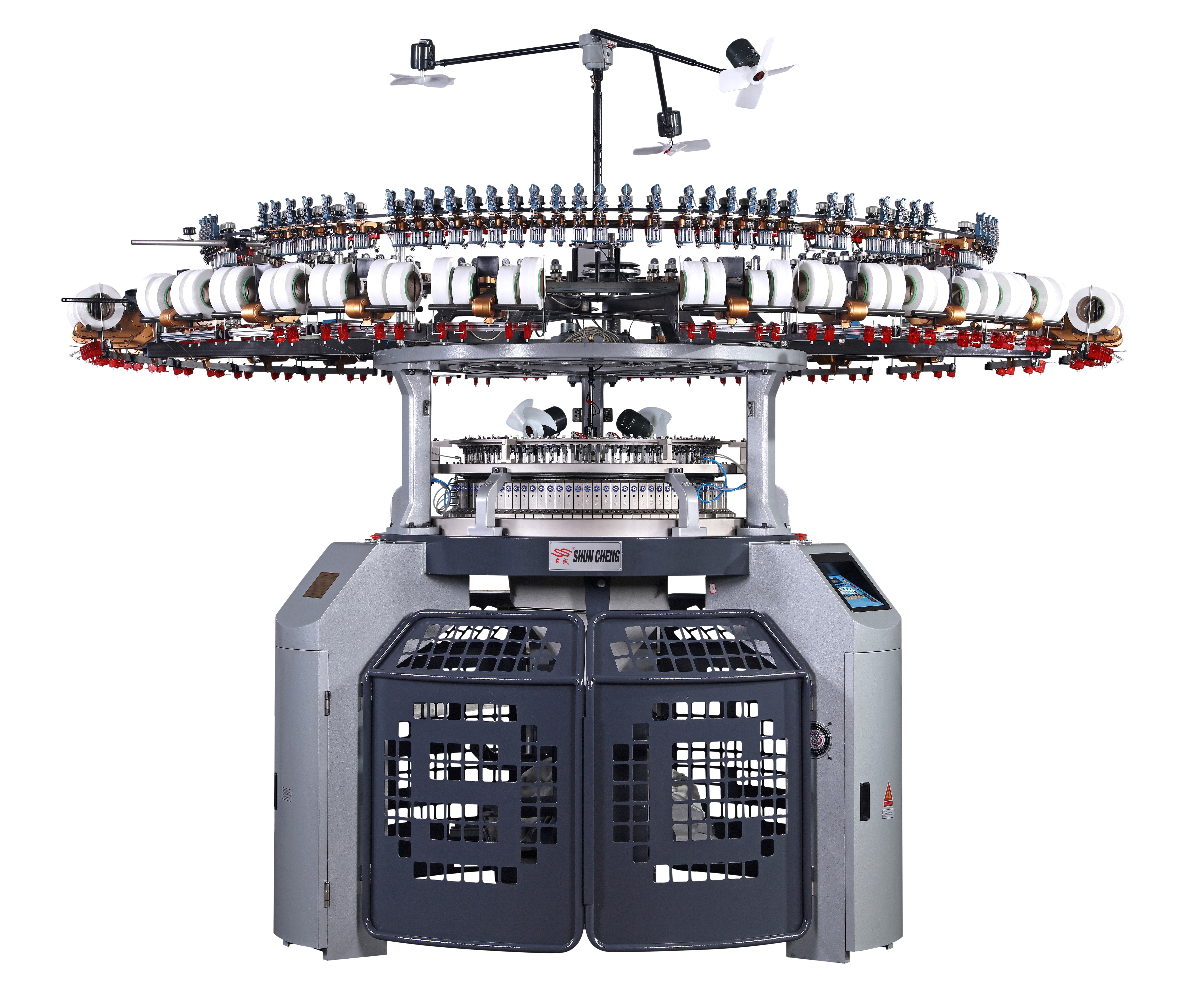

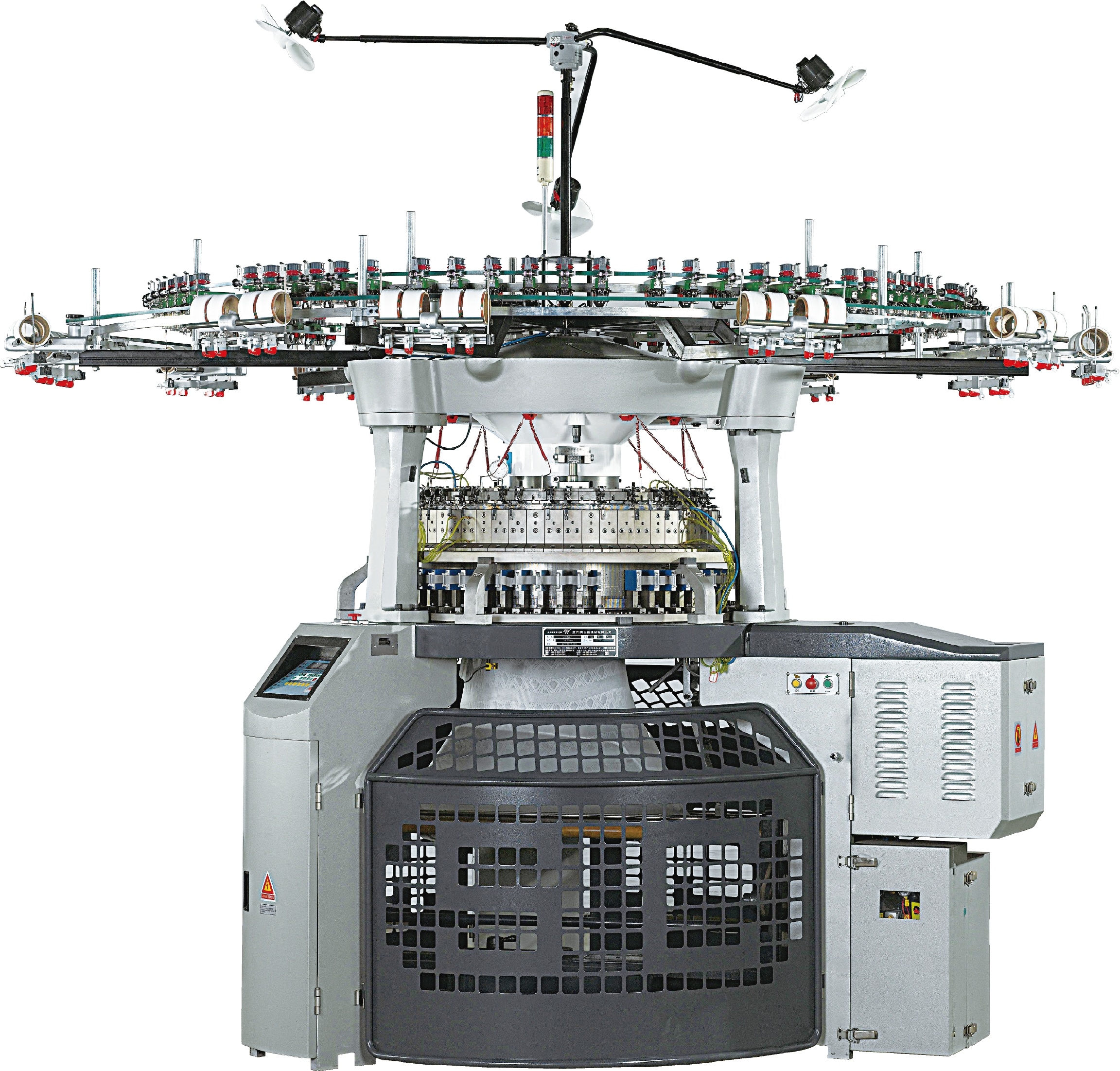

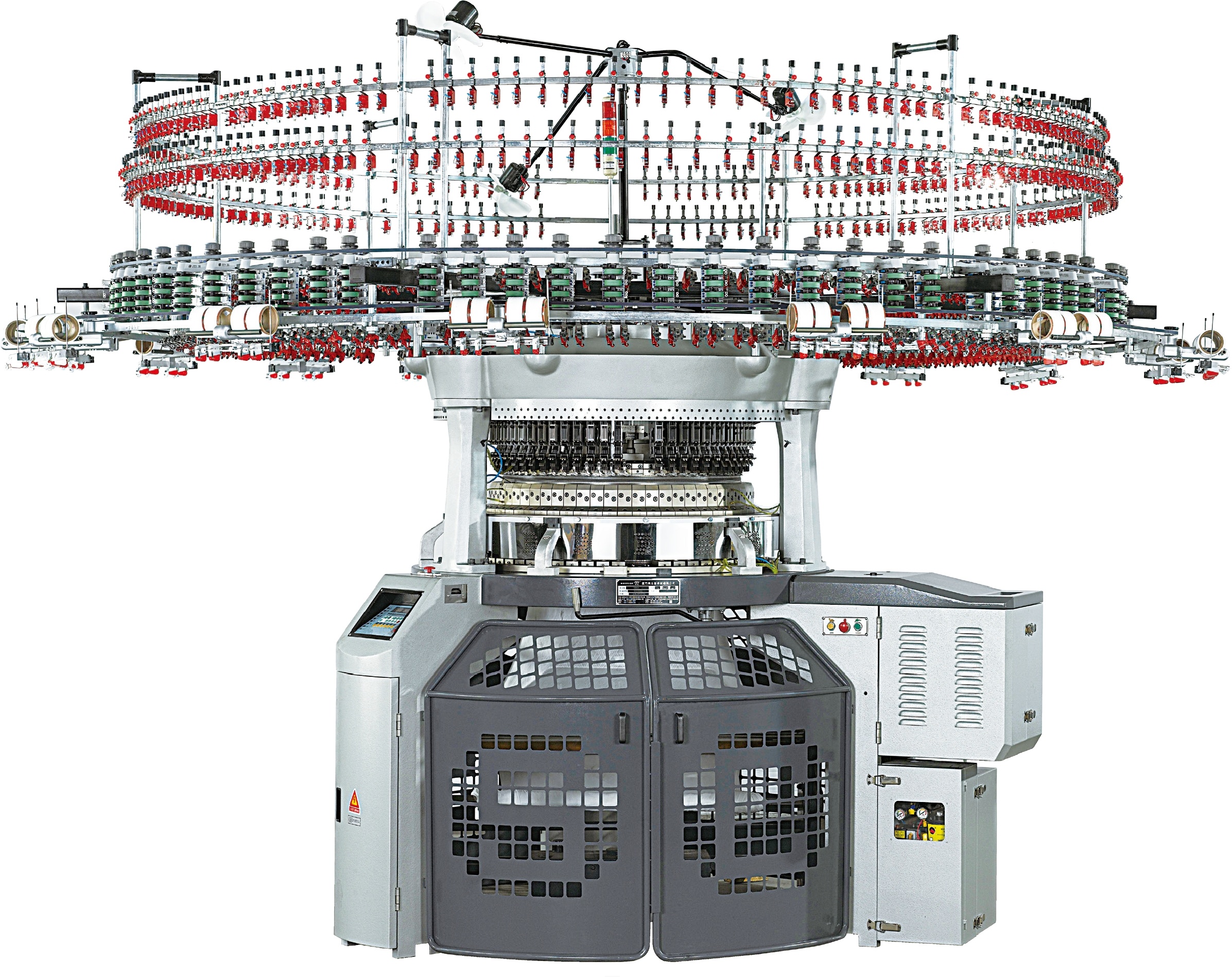

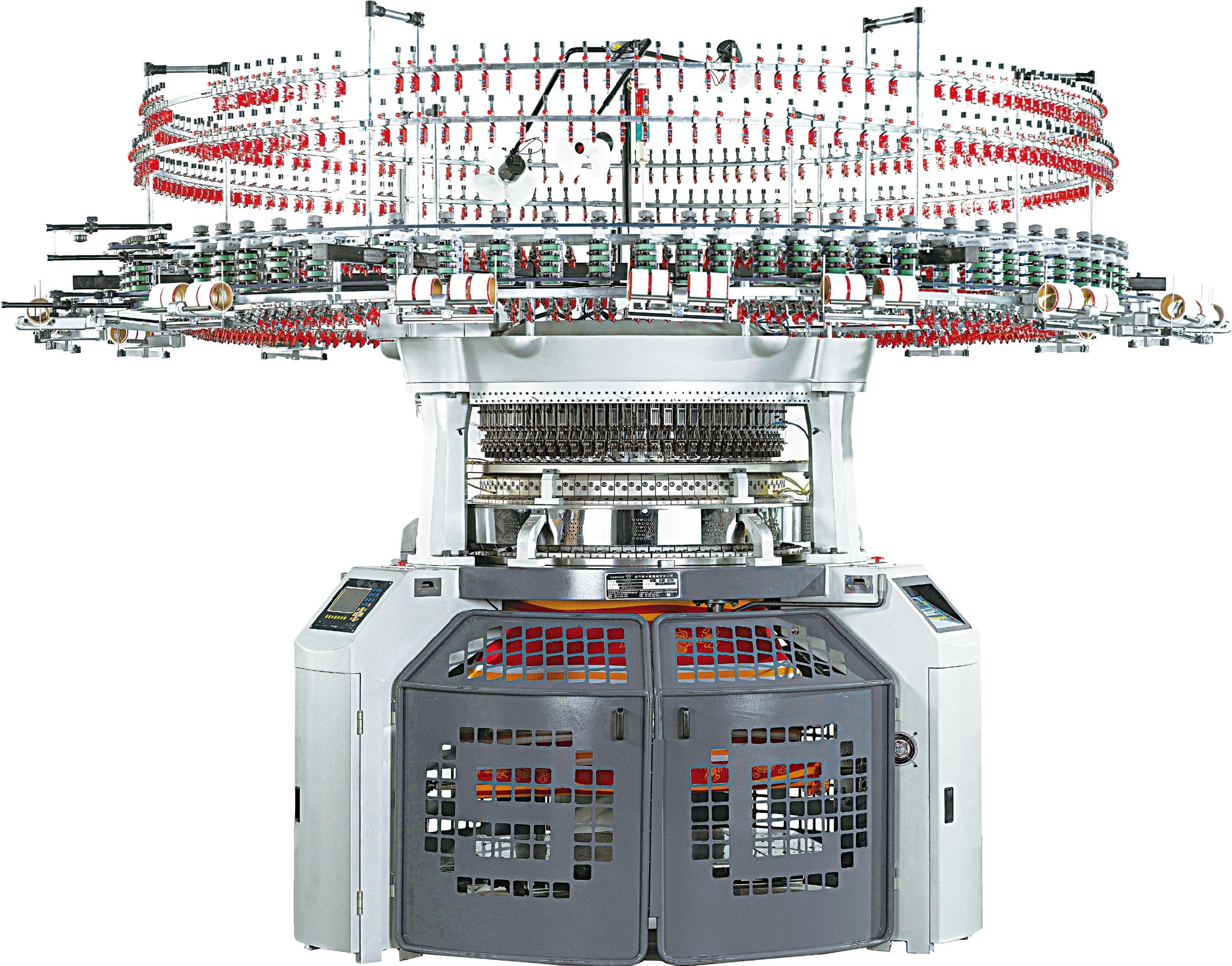

The machine selects needles in cylinder by actuator. It can knit varieties of patterns into jacquard beyond limitation. The selector unit can select needles for three ways of knitting including knit、miss、tuck.

Precise encode can calculate the position and zero-calibration-position of needle accurately. And a detector is added to assist zero calibration for accuracy of selection to ensure the total stability of the system.

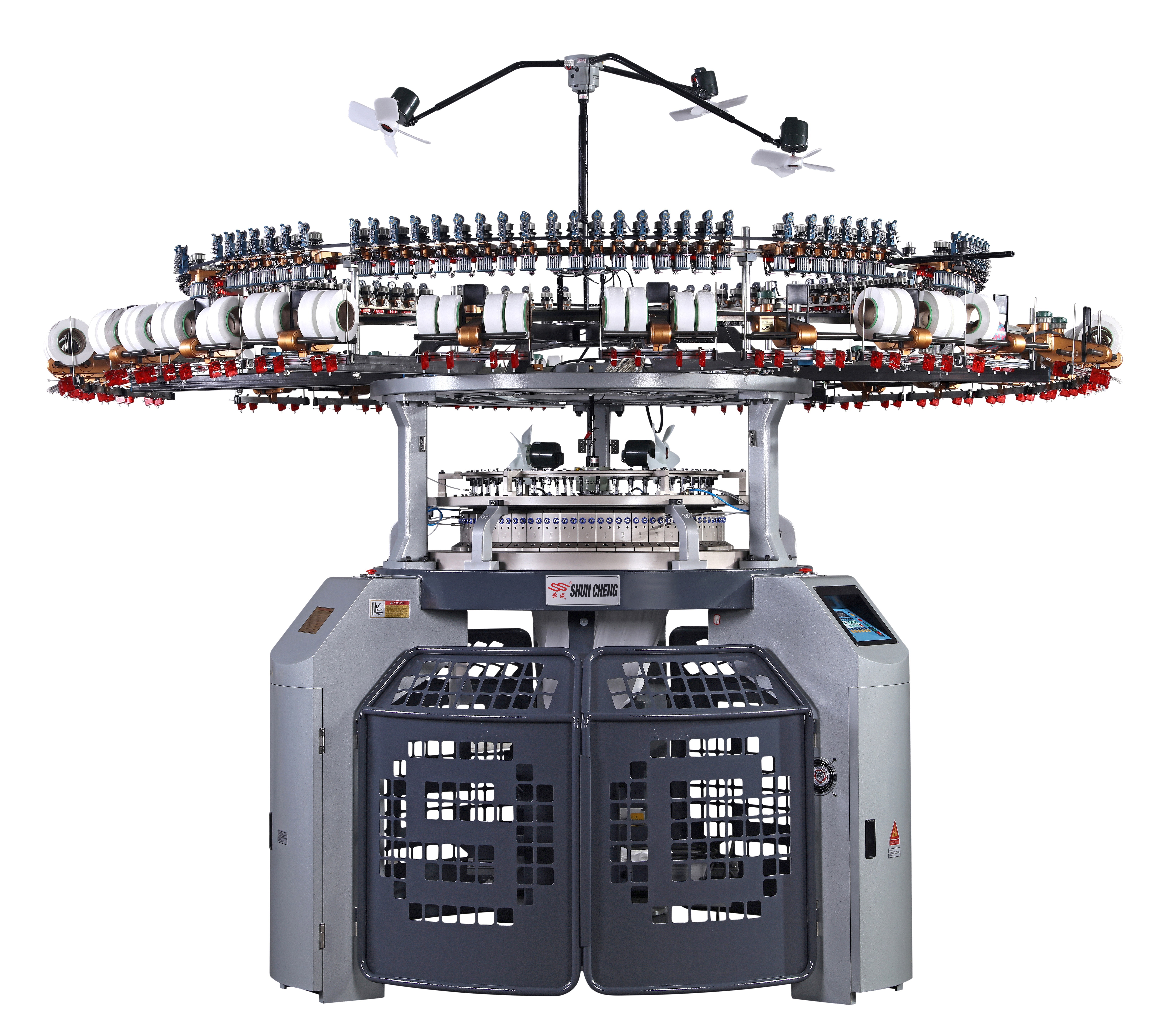

The jacquard circular knitting machine represents a significant advancement in textile production, offering unparalleled capabilities for creating complex patterned fabrics. Its primary advantage lies in its ability to produce intricate designs, such as detailed logos, geometric patterns, and floral motifs, directly into the knit structure. This eliminates the need for post-production processes like printing or embroidery, streamlining manufacturing and reducing labor costs. The technology behind a modern jacquard circular knitting machine allows for individual needle control, enabling the seamless integration of multiple colored yarns to form sophisticated and durable patterns that are integral to the fabric itself.

Another notable benefit is the remarkable versatility of this equipment. A single jacquard circular knitting machine can be configured to produce a wide array of products, from fine-gauge apparel like high-fashion sweaters and athletic wear to heavier textiles for home furnishings. This flexibility is crucial for manufacturers catering to dynamic market trends. Furthermore, fabrics produced on this machinery are known for their comfort and performance. The construction techniques allow for enhanced breathability and elasticity, making the textiles suitable for a range of applications where both aesthetics and functionality are valued.

In terms of production efficiency and economic operation, the electronic jacquard circular knitting machine offers substantial advantages. Its precision control systems optimize yarn usage, minimizing waste and contributing to more sustainable manufacturing practices. The ability to quickly switch patterns digitally facilitates small-batch and custom orders, providing a competitive edge. Ultimately, the use of a robust jacquard circular knitting machine empowers manufacturers to achieve a high level of creativity, operational efficiency, and product quality, solidifying its status as a vital asset in the modern textile industry.

Key words:

jacquard circular knitting machine factory

Related Products

Single Jersey Knitting Machine

-

Single Jersey 4 Tracks Circular Knitting Machine

The machine is better in heat dissipation, ease of operation, low failure rate and is capable of knitting various fabrics. The machine adopts four tracks on cylinder which provide the machine more maneuverability, smaller distance, easier and precise adjustment. It can help to manufacture all kinds of single jersey fabrics. Applicable material: cotton, synthetic fiber, blending, silk and artificial wool etc.

-

Single Jersey 4 Tracks Open Width Knitting Machine

Single jersey open width circular knitting machine is the machine which is used to produce many kinds of single jersey fabrics. Four track cams structure and universal needles which make it lower cost. Gears adopt oil-soaking design, through special treatment to prolong the life of gears and lower noise and quick rotation. Adopt open width system, make fabrics no fold mark and make the totally usage of fabrics, no waste of fabrics to reduce the cost.

-

Single Jersey Three-thread Fleece Circular Knitting Machine

-

Single jersey Terry circular knitting machine

Ce single jersey circular knitting machine Is One of the Main Spots Products of XING-QUANLONG With the Best Quality,With Professional Production Facilities,Welcome to Call

-

Single Jersey 4 Tracks Open Width Knitting Machine(high gauge)

Single jersey open width circular knitting machine is the machine which is used to produce many kinds of single jersey fabrics. Four track cams structure and universal needles which make it lower cost. Gears adopt oil-soaking design, through special treatment to prolong the life of gears and lower noise and quick rotation. Adopt open width system, make fabrics no fold mark and make the totally usage of fabrics, no waste of fabrics to reduce the cost.

Double Jersey Knitting Machine

-

Double Jersey Open Width Circular Knitting Machine

-

High Frame Double Jersey Interlock/Rib Knitting Machine

-

Double Jersey Open Width Circular Knitting Machine (high gauge)

-

Double Jersey Interlock Circular Knitting Machine

-

Double Jersey Rib Circular Knitting Machine

-

60” Double Jersey Open Width Circular Knitting Machine

Jacquard knitting machine

-

Double Jersey Computerized Jacquard Open Width Circular Knitting Machine

-

Double Jersey Computerized Jacquard Circular Knitting Machine

-

Double Transfer Rib Computerized Jacquard Knitting Machine

-

Double Jersey 4/6 Colors Full Computerized Auto Stripper Circular Knitting Machine

-

Single Jersey 4/6 Colors Full Computerized Auto Stripper Circular Knitting Machine

-

Single Jersey Computerized Jacquard Circular Knitting Machine

-

High Pile Computerized Jacquard Knitting machine

-

Single Jersey Computerized Mesh Jacquard Circular Knitting Machine

XING-QUANLONG: Your trusted jacquard circular knitting machine suppliers. We provide advanced, efficient textile solutions for global manufacturers. Partner with innovation

2.0 Intelligent Knitting Machine

Ask For A Quick Quote

We will contact you within 1 working day, please pay attention tothe email with the suffix "@xmgdab.com"